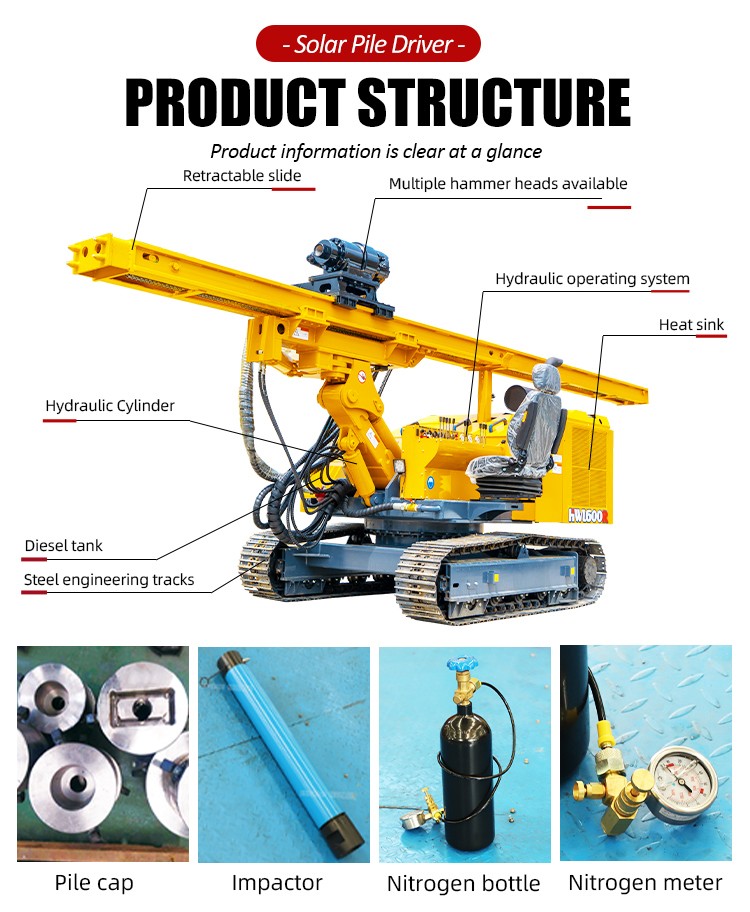

| Product number | HWL600R | |

| Hydraulic hammer model | 75/85/100 optional | mm |

| Hydraulic hammer flow | 50-110 | L/min |

| Impact frequency | 350-800 | bmp |

| Drill rod diameter | 75/85/100 | mm |

| pile height | 6 | m |

| Pile height sliding guide frame tilt angle | (Left)5(Right)5 | ° |

| Rack rotation angle | 360 | ° |

| Hydraulic system pressure | 22 | mpa |

| Gear pump displacement | 40+40+25 | ml/r |

| Driving speed | 3 | km/h |

| Vehicle weight | 7800 | kg |

| Engine power | 85 | kw |

| Engine rated speed | 2600 | r/min |

| Track shoe width | 350 | mm |

| dimensions | L*W*H 2375*1980*7760mm(working status) L*W*H 7760*1980*2375mm(Shipping status(The transportation height is the height with the hydraulic hammer head/hydraulic power head removed) | |

| Optional | |||

| Hydraulic drilling power head | model | HWQK350 | |

| Torque | 8000-12000(Optional) | N•m | |

| single maximum depth | 6 | m | |

| Maximum DTH diameter | 130-400 | mm | |

| Maximum spiral drilling diameter | 500 | mm | |

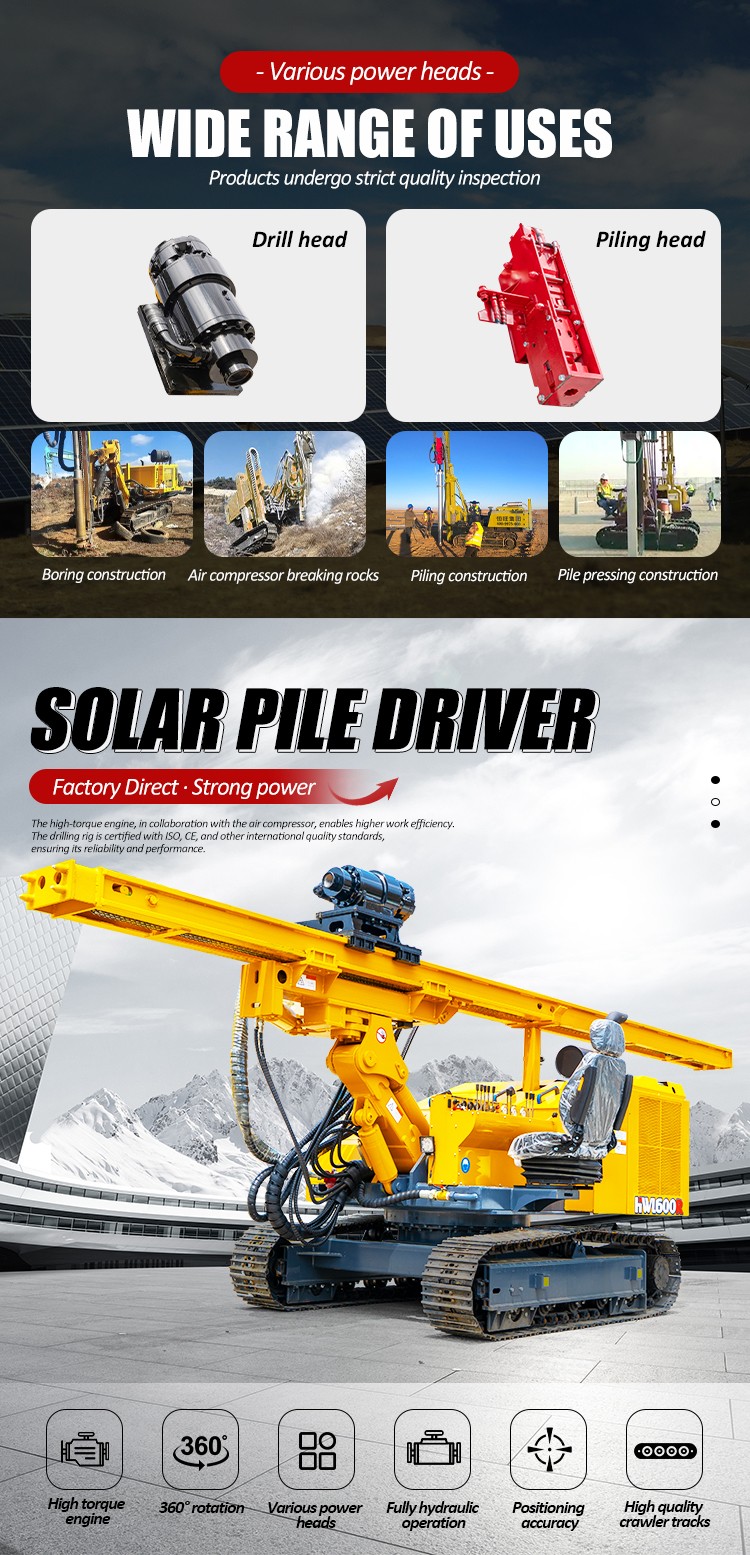

Main features:

1. Fuel-efficient and reliable power engine: The HWL600R piling equipment is equipped with a power engine that is designed to be fuel-efficient while delivering stable and high-performance operation. It ensures optimal power output while minimizing fuel consumption.

2. High-efficiency hydraulic system: The piling machine incorporates high-quality hydraulic components and undergoes a strict assembly process. This ensures the efficiency and reliability of the hydraulic system, enabling smooth and effective piling operations.

3. Stable and robust construction: The HWL600R is constructed using international high-standard raw materials, which guarantees the stability and durability of the overall structure. It is built to withstand demanding piling tasks in various environments, ensuring long-lasting performance.

4. Industrial aesthetic design: The equipment features an industrial aesthetic design, combining functionality with a visually appealing appearance. The design not only enhances its aesthetic appeal but also reflects the ruggedness and reliability of the machine.

The HWL600R is a piling equipment initially designed for early-stage piling in photovoltaic power stations. However, through research and development efforts and subsequent upgrades, it has been enhanced to be suitable for various piling projects in farms, pastures, orchards, and other applications.

With its versatile capabilities, the HWL600R can effectively meet the piling needs in a wide range of environments and construction scenarios. Whether it's for solar power installations or other agricultural and land development projects, the HWL600R offers reliable and efficient piling solutions. Its adaptability and upgraded features make it a valuable choice for different applications beyond its original design intent.

Quote now for the best price.